Efficient work preparation

With their many years of experience and expertise, our professional work preparers ensure the most favourable layout of the aluminium sheets. By efficiently dividing the created aluminium parts into the right plate(s), the material is used optimally.

Working method

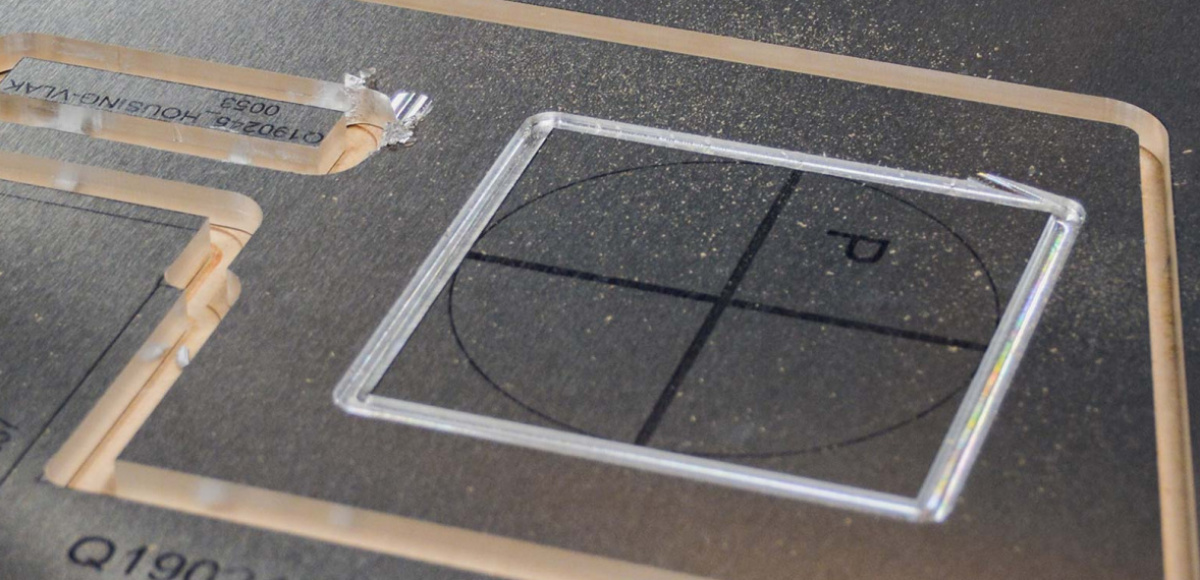

We work with smart planning to identify potential conflicts in the initial process and resolve them early on in the process. Efficiency is central to our process. With their many years of experience and expertise, our work planners ensure the most favorable layout of your plates with our CAD/CAM software. By efficiently dividing the created aluminium parts into the right plate(s), the material is used optimally.

After nesting, all data must be made usable for the milling machine. This is done by determining the most suitable milling route. This milling route is written out to the required machine code.

We will be delighted to give you appropriate advice, taking into account cost-saving possibilities.

Contact Snijtechniek Brabant for your made-to-measure aluminium parts

Our professional work preparers, with their years of experience and expertise, will of course ensure the most favourable layout of your plates and cutting route. Ask about these cost-saving possibilities.

Contact us